Considerations for the use of high-purity recombinant growth factors in cellular agriculture applications

Last updated: 1st December 2023

This article provides scientific and related background to support raw materials selection and is not intended to provide regulatory advice.

Cultivated meat is a nascent industry with a developing regulatory framework, with distinct regional differences. There are however some shared themes across regulatory frameworks and best practice. In general, growth factors and other recombinant proteins used at low concentrations in the cell culture media for cell maintenance, differentiation and/or maturation are considered food processing aids, or the equivalent.

In the UK/EU these are considered under EC 1333/2008 article 3.2(b). There is no legally defined list of approved processing aids. Under UK/EU guidance on genetically modified microorganisms for the production of food processing aids, growth factors would typically be considered category 1 for highly purified proteins (sometimes 2 if a less pure complex mixture is used) (1).

Within the UK and EU, cultivated meat is considered a novel food and as such falls under the scope of Regulation (EU) No. 2015/2283. In response to this classification, the Food Safety Agency commissioned an internal report into the potential hazards to the consumer associated with the production and consumption of cultured meat. Following a literature review of 154 papers discussing cultured meat as a technology, the following main themes that apply to growth factors were highlighted.

1. Contamination from components used in cell culturing

Consideration: biological components derived from animals and bacteria can transfer disease into culture or pose a risk of bacterial contamination.

All Qkine products are manufactured in a dedicated animal-free laboratory. Raw materials and consumables used within the Qkine production processes do not contain or derive from animal or human tissue, cells or body fluids and no animal or human tissue, cells or body fluids are used at any stage of their manufacture.

E.coli host cell protein and host cell DNA testing using industry-accepted analytical tests show no detectable host cell (E.coli) proteins or DNA in our products. This confirms that no recombinant genes or microbial cells remain in the product.

E.coli has appropriate precedent as a host for fermentation of food processing aids and food enzymes (2). In addition, there is no record in the literature of genes coding for toxins or anti-nutrients being present in the standard production strain, E.coli BL21.

Consideration: compounds used in cell culturing could be absorbed by the cell or become associated with the cell wall and transferred into the final product. An understanding of how these compounds could bioaccumulate/be present in the final product and how they are removed or are at an acceptable exposure level needs consideration.

Growth factors are naturally occurring proteins present in meat. They are subject to digestion processes and denaturation during cooking. Several growth factors are also produced by cells in culture, so determining the remaining levels of exogenously added growth factors may be challenging.

Some growth factors have extensively documented short half-lives in standard cell culture conditions, such as FGF-2. It is generally accepted that growth factors are considered thermolabile with low stability. The currently accepted view is that bioaccumulation leading to their presence in the final product is an unlikely outcome (see: recent FDA memorandum on Upside Foods first regulatory filing).

2. Cell culture infections from contaminated reagents

Consideration: risk of infection or production of toxins due to microbial contamination (or reduction of cell mass yield affecting process efficiency).

- Bacterial, yeast and fungal infections

Qkine products are tested for sterility (low bioburden) according to Ph.Eur, USP, JP as part of the routine QC and manufacturing lot release process.

- Mycoplasma infections

All Qkine product lots are negative for mycoplasma when tested in both ribosomal RNA hybridization and luminescence assays.

- Viral contamination

Qkine products are purified from an E.coli microbial expression system utilising animal-component free manufacturing process. They are free from viruses and other pathogens that may be present in an animal expression system.

3. Allergens

Consideration: potential allergens may be present due to the added growth factor or production host

According to FAO/WHO rules a protein with more than 35% sequence identity spanning a window of 80 amino acids or the presence of an identical hexamer (peptide of six amino acids) compared to at least one known allergen is to be regarded as a potential allergen.

The following Qkine products were compared with the University of Nebraska’s database of known allergens. No product was sufficiently similar to the allergenic protein sequences to be considered a potential allergen.

| Qk001 | Human, mouse, rat, bovine, porcine Activin A |

| Qk005 | Human, mouse, rat, bovine, porcine Activin A PLUS |

| Qk025 | Human FGF2 (145aa) |

| Qk027 | Human FGF2 (154aa) |

| Qk002 | Zebrafish FGF-2 |

| Qk040 | Bovine, porcine FGF-2 (145aa) |

| Qk056 | Bovine, porcine FGF-2 (154aa) |

| Qk047 | Human, bovine, porcine IGF-1 |

| Qk041 | Human, bovine, porcine IGF1 LR3 |

| Qk060 | Bovine HGF |

| Qk061 | Porcine HGF |

| Qk013 | Human HGF |

| Qk010 | Human, bovine, porcine TGF-β1 PLUS |

| Qk011 | Human EGF |

| Qk064 | Porcine EGF |

| Qk045 | Human, bovine, porcine NRG-1 |

| Qk044 | Human PDGF-BB |

| Qk018 | Mouse LIF |

| Qk036 | Human LIF |

Soy

Soy is an allergenic substance whose presence in food must be indicated on labelling according to EU law. The microbial culture media used at Qkine is animal-free; tryptone manufactured from casein (milk) used in traditional microbial culture media is replaced with soya peptone.

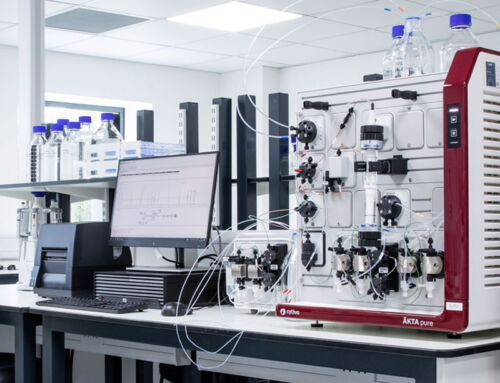

Qkine growth factors have minimal direct contact with cell culture media during the early stages of the manufacture process. The proteins then undergo multiple purification stages before the purity of the final product is confirmed by several techniques to ensure the reliability of the results.

Due to the highly purified nature of our products, it is reasonably considered that soya is not present in the final product.

4. Other considerations

Endotoxin levels

Endotoxins are often present in food processing aids and may be present in cell culture media and other consumables. Care should be taken with overall endotoxin levels in media as this may impact cell viability or growth characteristics. Qkine growth factors are manufactured using proprietary processes to ensure industry-leading low levels of endotoxins. Endotoxin levels are measured in every manufacture lot using an FDA-approved standard test, all products have endotoxin levels <0.1 EU/ug.

Engineered, non wildtype growth factors

Several recombinant proteins, including growth factors, are produced as shorter forms of the protein with the native protein sequence retained. For some proteins, such as Activin A, this is essential to produce an active protein. These are usually considered wild-type.

In some cases, amino-acid substitutions may be required in the natural sequence to either facilitate production in a microbial fermentation system or improve bioactivity or stability. Often these sequence amendments are minor.

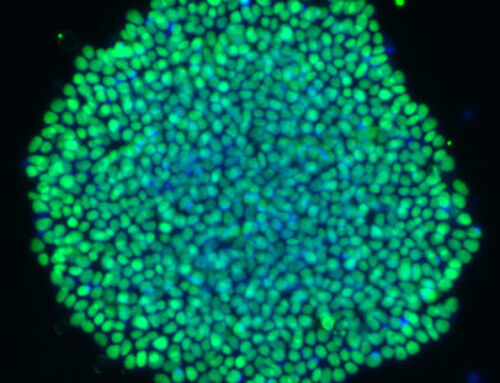

Sometimes more extensive engineering is used to drastically improve the performance or stability of the growth factor, a good example is the development of thermostable proteins such as FGF2-G3, where protein engineering was used to increase the functional half-life from <24h to >7 days. This can significantly reduce growth factors requirements, culture media costs and improve cell mass production and homogeneity of the cells (particularly iPSC derived cultures). However, applying these highly engineered proteins may require a more thorough risk assessment.

Protein tags

These are non-native additional protein sequences added to the N- or C-termini of the protein to aid purification, a commonly used tag is a His-tag. This non-natural sequence may be flagged as a regulatory concern depending on the regulatory authority and personnel. Please also note that His-tag purification using nickel columns is not scalable and expensive, so is unlikely to be appropriate to meet future demand. It is advisable to avoid proteins containing any protein tags. You may need to ask your supplier if protein tags are used as sometimes these are not declared in the product information. All Qkine proteins are tag-free.

Species-specific growth factors and the use of human growth factors

It is generally accepted that best practice is to use growth factors from the target species for reasons of consumer acceptance and species-specific activity including differences in receptor binding and efficacy in some cases. Some growth factor protein sequences are highly conserved and 100% identical across species, including for instance several TGF beta family proteins.

There is currently a lack of commercial availability of cultured-meat and fish relevant species-specific growth factors, so often human proteins, or indeed bovine serum, are used as a surrogate. It’s advisable to determine the conservation of protein sequence when selecting appropriate growth factors and switch to species-specific proteins if feasible.

5. Analytical methods conducted at Qkine

SDS-PAGE

SDS-PAGE (sodium dodecyl sulfate – polyacrylamide gel electrophoresis) is a method that separates protein by its mass. Every lot is run on an SDS-PAGE gel to ensure there is no protein degradation or protein contaminants in the sample.

Mass spectrometry

Mass spectrometry analysis is used to confirm the molecular mass of the intact protein and to reveal any heterogeneity or protein contaminants that would not be evident from SDS-PAGE analysis. The resultant mass is compared with the calculated mass of the protein with the assumption that all the cysteines are disulfide-linked. Qkine conducts mass spectrometry analysis on every protein lot to confirm purity.

UV-Vis spectrophotometer

The OD 260/280 ratio is a valuable tool in protein purification and indicates the purity and composition of a sample.

Mycoplasma testing

Mycoplasma readily infect cell cultures and are challenging to remove from a facility. It’s essential all raw materials for cell culture media, and cell lines are mycoplasma free. All Qkine proteins are tested to ensure they are free from mycoplasma contamination.

Sterility testing

All manufacturing lots undergo sterility testing as part of the lot release process.

Host cell DNA and host cell protein

These analytical tests are provided on a custom basis if required. Evaluation of representative proteins has confirmed the removal of host cells and host DNA.

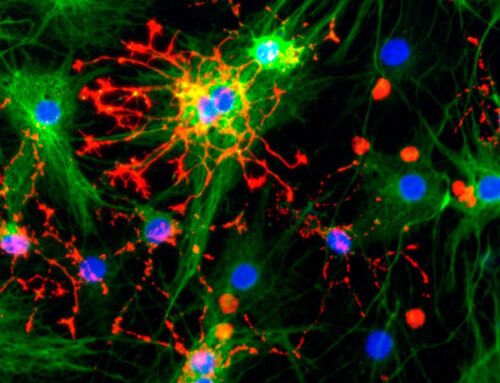

Bioactivity assay

The bioactivity of all Qkine proteins is measured in a quantitative luciferase assay, or equivalent. Every manufacturing lot is tested and compared to a reference lot, to ensure consistent and reproducible bioactivity.

References

- Guidance on the risk assessment of genetically modified microorganisms and their products intended for food and feed use

EFSA Journal, 2011 - List of “Microbiological agents as notified to EFSA” from 2007, in the context of technical dossiers to EFSA Units, for intentional use in feed and/or food or as sources of food and feed additives, enzymes and plant protection products (PPPs) for safety assessment.

Zenodo, 2023 - Guidance on the characterisation of microorganisms used as feed additives or as production organisms (refer to page 13 – fermentation products)

EFSA Journal, 2018

Animal-free growth factors for cellular agriculture

We are confident that the quality and bioactivity of our recombinant proteins will ensure that you achieve your research goals. Our dedicated team of stem cell specialists is available to answer any queries you may have and to give expert support when required.