Transitioning to a fully animal origin-free

recombinant protein manufacturing process for ethical and sustainable bioproduction

recombinant protein manufacturing process for ethical and sustainable bioproduction

Transitioning to animal-free manufacturing of growth factors is a crucial step toward more ethical, safe, and sustainable bioproduction methodologies.

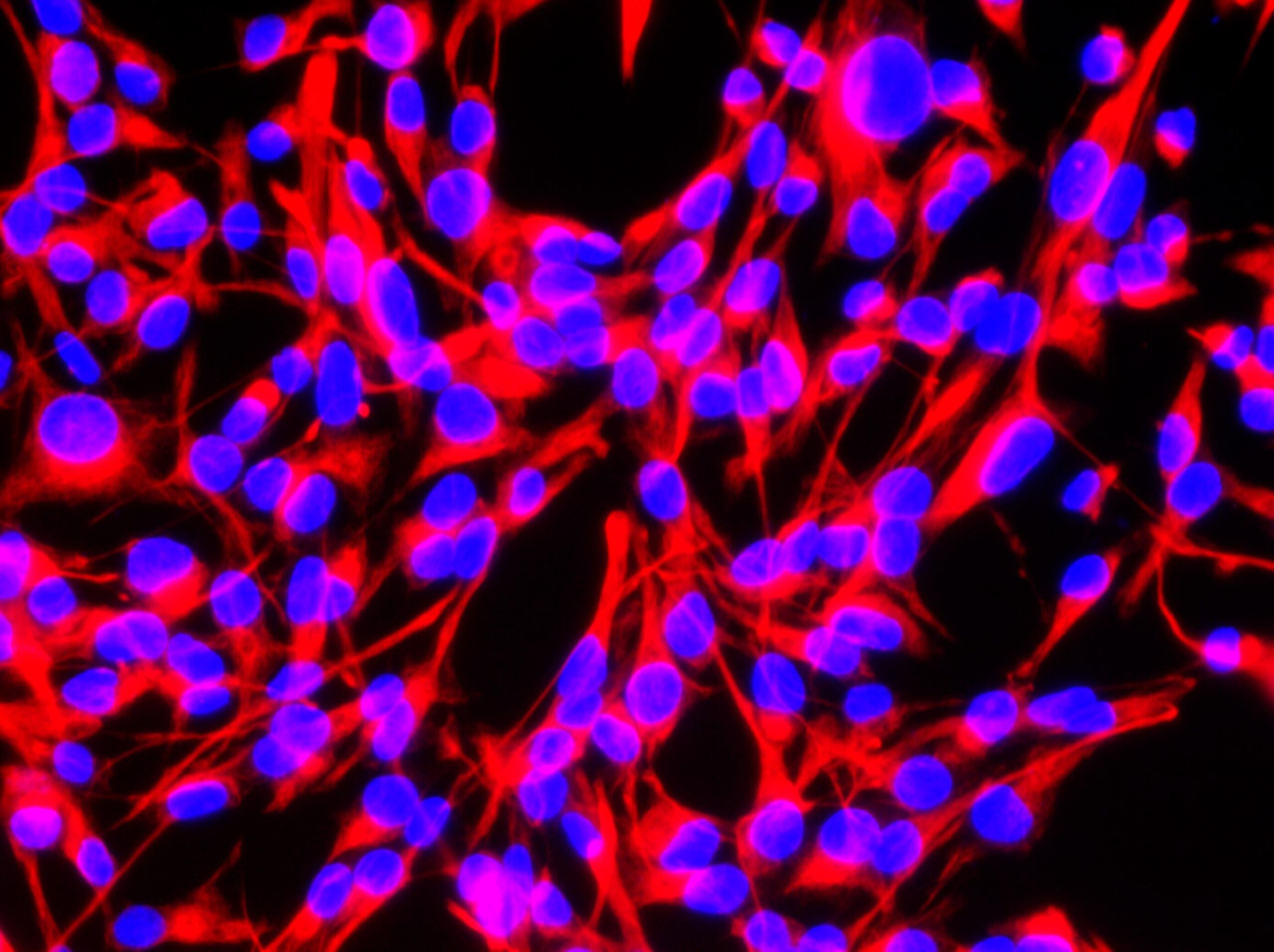

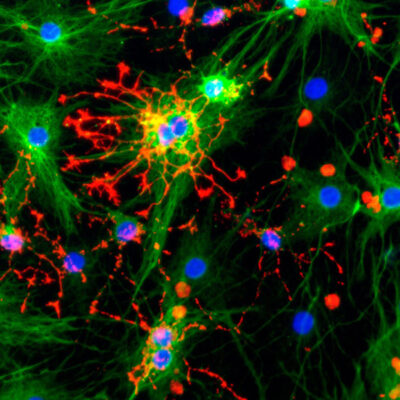

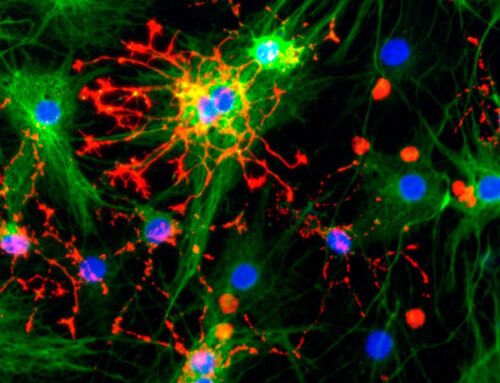

Animal origin-free manufacturing enhances the safety and consistency of growth factor production by eliminating any risk of animal-derived contaminants in the final product, ensuring the highest levels of recombinant protein purity and efficacy. This approach meets the growing focus on cruelty-free and sustainable practices and aligns with targets to reduce the use of animals and animal-derived products in scientific research and biomanufacturing.

Moreover, adopting animal origin-free growth factors and cytokines smooths the transition to manufacture of cell-based therapies and tissue engineering in regenerative medicine, fostering innovations that can improve human health outcomes.

Animal-free growth factors are also required in other regulated applications, such as cultivated meat, which aims to create sustainable, ethical, and scalable alternatives to traditional meat production.

Understanding the terms

Animal Origin-Free (AOF)

AOF refers to products or processes that do not involve any materials, ingredients, or components derived from animals at any stage of their production process. This term is used in several industries, including food, pharmaceuticals, cosmetics, and biotechnology, to indicate that the product is entirely free of animal-derived substances.

Points to consider:

Animal-Derived Component-Free (ADCF)

The terms ADCF and AOF are often used interchangeably but have distinct nuances depending on the context.

In general, ADCF refers to products or processes that do not come from direct animal-derived ingredients.

However, ADCF may still involve processes, reagents or equipment that use animal products indirectly e.g. products made from polyethylene and polypropylene, such as flexible tubing, cylindrical tanks, bags, and capsule filters, that contain animal-derived components such as stearic and other long chain fatty acids. These “slip” agents are rendered from tallow, or beef fat, and give the products lubricity and prevent the polymers from sticking to metal surfaces during extrusion or mold release.

Whereas ADCF focuses on the absence of direct animal-derived ingredients or components, AOF is a stricter standard of manufacture that ensure the entire lifecycle of the product is free from animal-derived reagents and materials .

Quick guide: AOF or ADCF?

| Difference between animal-origin free (AOF) & animal-derived component free (ADCF) | AOF | ADCF |

|---|---|---|

| Raw materials used directly in the product or as a starting material (e.g. E.coli growth media) are not derived from animal or human tissue, cells or body fluids | ✔ | ✔ |

| Raw materials used directly in the product or as a starting material do not contain animal or human tissue, cells, or body fluids at any stage of their manufacture process | ✔ | ✔ |

| Consumables used within the Qkine production process (e.g. filters) are not derived from animal or human tissue, cells or body fluids and no animal or human tissue, cells or body fluids are used at any stage of their manufacture process. | ✔ | ✗ |

AOF manufacturing within Qkine

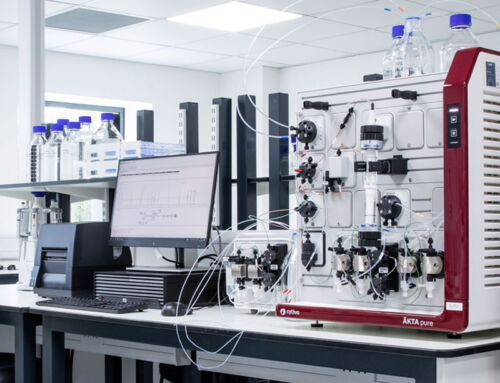

Qkine manufactures recombinant proteins in a dedicated animal-free, beta-lactam-free laboratory located in an ISO 9001:2015 certified facility located in the UK.

Our animal origin-free recombinant protein manufacturing process ensures every stage is defined, documented, and controlled to provide an animal-free product. Qkine proteins are manufactured in an E. coli microbial expression system, with no use of baculovirus on-site. Our quality team assesses every component used during the manufacture of our products and requires certification and validation of their animal-free status.

“During manufacturing, each production lot undergoes rigorous testing through various quality control assays to ensure consistently high quality in every batch. This commitment is embodied in our nine-point quality pledge, which includes the industry’s strictest endotoxin level pass criteria, along with standard mycoplasma and sterility testing. Moreover, our products are guaranteed free from BSE/TSE.”

David Cavanagh, Head of Manufacture & Operations, Qkine

The move to full AOF manufacturing at Qkine

All products manufactured by Qkine are now certified AOF.

Until recently, a few products in the FGF family of growth factors required the use of a derivatized heparin-based chromatography matrix for purification, leading to these products being certified ADCF ie. the matrix was not present in the final product but was in contact with the final product.

During the past year, the Process Development team and manufacturing teams at Qkine have prioritized the systematic removal of these heparin-based columns from our manufacturing processes and the replacement of our current stocks of ADCF batches of product with certified AOF proteins.

This work involved identifying and testing replacement columns for each specific protein that was previously purified using a heparin-based chromatography column. Additionally, it encompassed scaling up manufacturing and fully validating and documenting the new processes to ensure that each newly developed AOF replacement product matches the high quality and standards, such as purity and bioactivity, of those prepared using an ADCF process. The resulting efforts led to the successful transition of all existing ADCF products across a 6-month period, facilitating Qkine’s complete shift to AOF manufacturing.

“We are deeply dedicated to producing high-purity, animal-free growth factors. A key priority has been eliminating animal-derived heparin-based components from our manufacturing process. This has allowed us to transition to a completely animal-free production facility for all our products – a significant achievement that showcases our team’s commitment to quality and excellence.”

Dr Andy Day, VP Scientific Operations, Qkine

Qkine remains committed to achieving our environmental and sustainability goals and we are continually improving processes across the company and innovating to provide new and improved growth factors and cytokines to support the stem cell community.

We are a science-led company and are always happy to help if you have any questions or would like to collaborate.

Please contact our team at support@qkine.com

Committed to manufacturing bioactive proteins of the highest quality

to enhance scientific outcomes and improve reproducibility.

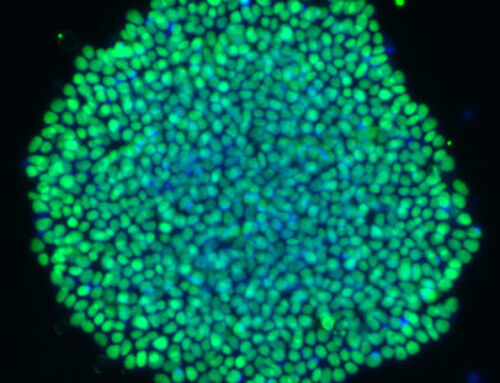

Our robust animal origin-free manufacturing platform, along with rigorous quality control procedures, ensures exceptional bioactivity and consistent performance from lot to lot, guaranteeing outstanding performance in your applications.

We proactively leverage our expertise in manufacturing and protein engineering to develop unique optimized proteins designed to address fundamental biological, translational and scalability challenges.

Our product portfolio comprises growth factors and cytokines tailored for stem cell and organoid culture, as well as biomarkers and attachment factors. We actively support emerging fields such as cellular agriculture, regenerative medicine, synthetic hydrogels, organ-on-a-chip technology, and bioprinting.

To ensure absolute reproducibility and optimize scientific outcomes, all our products rigorously adhere to the Nine-point Qkine Quality Commitment.

Featured resources

Sustainability

Sustainability is a crucial part of building a better future, and we have made it an integral part of our company values.