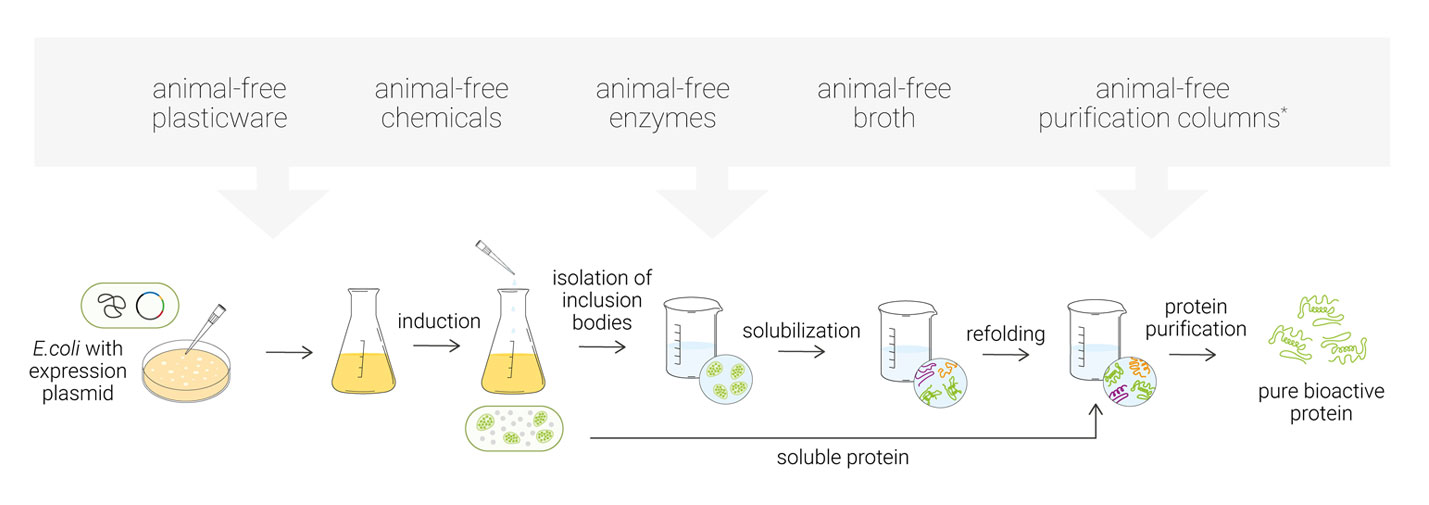

Growth factors are critical components of cell culture media and provide a carefully orchestrated set of biochemical signals to control cell growth and fate. High purity, animal origin-free and optimized growth factors produced in an efficient microbial fermentation process currently provide the most reliable and reproducible solution for cultivated meat and cellular agriculture.

Growth factors and other recombinant proteins used at low concentrations in the cell culture media for cell maintenance, differentiation and/or maturation are considered food processing aids, or equivalent.

We provide extensive quality analysis, documentation and support with novel food dossier preparation. Qkine food grade growth factors are manufactured in the UK under an ISO 9001:2015 quality management system with food manufacturing HACCP regime in an allergen-free process. Additional documentation available for these produce include full raw materials traceability, protein allergen analysis, CoO, CoA, beta-lactam-free and animal origin-free certification.

Overview of Qkine high quality food grade growth factors and cytokines for cultivated meat, fat and dairy bioprocess development and optimization

Qkine food grade growth factors are manufactured in an ISO 9001:2015 certified facility in the UK with a food manufacturing HACCP regime established. All Qkine manufacturing is animal-orign free and a process allergen isolation system is in place.

Qkine high quality food grade products are intended solely for use as food processing aids, ex vivo cell manufacturing and research use. Not for direct human consumption, therapeutic or diagnostic use. The authorization of novel foods, including the use of growth factors as food processing aids, is regulated by regional government agencies. The use of our products as food processing aids in novel foods requires the end-user to obtain the necessary regulatory approvals.

Qkine have QC procedures which are targeted around removal of host cell proteins to ensure the highest level of purity in food grade growth factors.

We guarantee >98% protein purity due to assay limits, but we are confident that the true result is higher. To ensure purity, every lot is tested using mass spectrometry, ELISA and overloaded SDS-PAGE gels to ensure that there are no host contaminants, aggregates, or degradants.

Utilizing animal origin-free recombinant proteins eliminates variations arising from trace animal components, promoting improved cell culture consistency. All our recombinant proteins mitigate the risk of contamination by mammalian pathogens, enhancing the reliability of cell products.

Qkine high quality food grade growth factors are manufactured under a HACCP regime to ensure the highest levels of food safety.

All Qkine growth factors and cytokines have exceptional lot-to-lot consistency. Every lot is checked during a stringent QC process to ensure it has the same bioactivity as prior lots and to ensure reproducibility.

This minimizes the need for optimization in large scale or long term cultures, as consistent bioactivity is guaranteed from every lot.

Current industry standards require endotoxin levels in growth factor lots to be less than 0.5 EU/ml, however the lower the better, and companies such as Qkine impose internal standards of <0.1 EU per µg protein.

Animal origin-free manufacturing offers greater supply chain stability and contributes to higher lot-to-lot consistency and reproducibility. This ensures that researchers can scale up production relying on consistent quality, reducing the need for extensive quality control measures and optimizing resource utilization.

High quality food grade manufacturing process control

As part of our ongoing commitment to quality in every aspect of the company, food grade protein production is taken into consideration from the very earliest planning stages of design and development. Before being incorporated into a procedure, newly-sourced materials must be reviewed and approved by our Quality team.

We continuously work with our suppliers to confirm and certify that the chemical components used within the manufacture of Qkine products are derived from non-animal and non-human sources and that the processes and components used in their own manufacture are animal origin-free.

Every stage of the Qkine animal origin-free protein manufacturing employs Standard Operating Procedures (SOPs). SOPs are fundamental to assure consistency from lot to lot and guarantee the highest quality of products.

Qkine is ISO 9001:2015 certified for development, manufacture, and supply of proteins and related products, in addition our food grade proteins are manufactured under a HACCP regime.

Every component used during the manufacture of our products is assessed by our Quality team.

High quality food grade documentation

Comprehensive information about applicable product hazards, safety precautions and management of the product within the workplace. The information is presented using the 16 sections detailed in the Globally Harmonized System of Classification and Labelling of Chemicals.

HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Allergen analysis results for each high quality food grade product are provided to assist our customers to comply with legal requirements and best practice around allergen labelling.

Qkine manufactures recombinant proteins in a dedicated animal-free laboratory with every stage of the manufacture process defined and controlled to provide an animal origin-free product.

Full traceability in supply and lack of toxicity or contamination in the Qkine expression system is available on request.

Formal, signed document detailing the results of the quality control of each manufactured lot in an easy to read format. Also includes the lot expiration date, shipping, storage and reconstitution information and the SKUs covered by the certificate.

Formal, signed document detailing the country of origin. Also includes the lot expiration date, animal-free status, regulatory compliance details, BSE and sterility information, shipping, storage and reconstitution information and the SKUs covered by the certificate.

The CAS number and concentration of all materials present in the final formulation, additional to the recombinant protein, are listed in this product-specific document.